How it works?

Easy of use

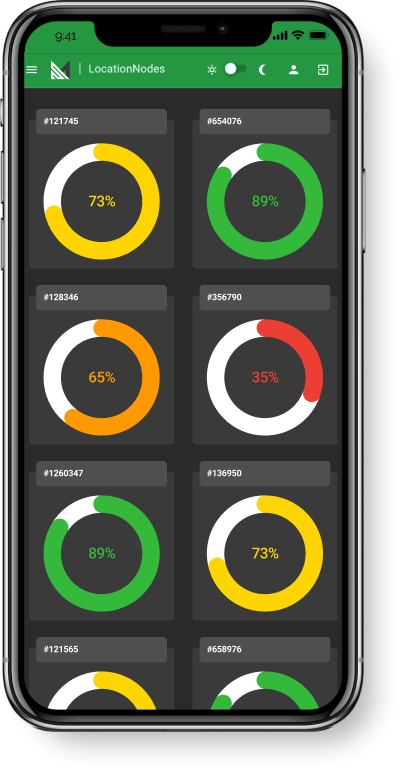

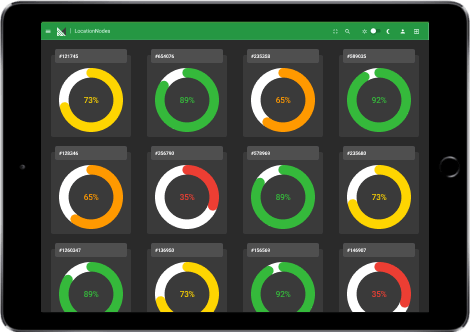

It is now possible to monitor the operation and diagnose the equipment condition without stopping the work process, using a minimum of time and technology. For example, your laptop, tablet or smartphone.

Accurate accounting

Automatic registration of incidents and downtime, the efficiency calculation of individual machines and operators. Control the production plan implementation, detect threats with immediate results displayed on your screen in real time.

Immediate response

The platform collects advanced analytics on the equipment operation in a general and individual order. The analysis results are converted into reports and specific recommendations. Manufacturing personnel are immediately notified when a problem is identified that requires attention.

Signs you need Machine Signals in your manufacture

Output

It is not clear why the entire machine park and operators stable operation results in different implementation of the manufacturing plan.

Stocktaking

In manufacture, there is no control over the production of a specific equipment piece.

Breakdowns

You cannot calculate among the machines total number the increased energy consumption, vibration or noise of one of them.

Downtime

You are forced to stop the workflow to diagnose all the machines in your manufacture.

How can Machine Signals help you streamline your workflow and avoid unnecessary costs?

Efficiency

We offer you an automated platform for total workflow monitoring.

Total control

Since the platform installation, your manufacture is under control: all the work nuances of the machine park will be recorded and entered into the reporting database.

Complete reporting

You will see what parameters influenced the work plan implementation, what your employees are doing, what equipment needs to be repaired or replaced. You will manage to prevent the problem before it appears, without having to stop the work process.

Machine Signals technical capabilities

The application has a clear and easy-to-use interface with flexible settings. This allows the system to combine the notification system with the staffing table and notify the employee who is at the workplace right now.

- Equipment loading control

- Equipment downtime control and classification

- Control of equipment operators labor discipline

- Alerting responsible workers about abnormal and requiring attention situations in manufacture

- Providing responsible employees with analytical reports

- Constant control energy consumption each piece of equipment

- Calculation of energy efficiency key indicators

- Notification of service and repair services in an accident case

- Notification of responsible persons about the workpieces lack, the registration lack of the operator on the equipment, etc.

- Customize your own alerts

What do you need to install and use?

- The system consists of a cloud service and a set of equipment installed at a controlled facility.

- The kit includes: a set of nodes (agents) installed on each individual machine and a gateway that provides data collection and transmission to the cloud service.

- The connection is provided by a fully Autonomous, stable MESH network that does not require additional hardware or complex infrastructure.

- The system can be easily deployed even in remote locations, or on mobile platforms.

Development of a personal solution

Flexible configuration

The modular architecture allows us to assemble only those sensors and sensors that are necessary for you.

Original development

We do not resell other people’s products, we develop and manufacture all the components ourselves, which means that it is possible to adapt the solution to your special requirements.

Work for you

We are ready to discuss your expectations from working with the platform and their further implementation for the individual needs of your production.